Timing Belts

Precision Synchronisation for Reliable Timing

Leopard Intertrade’s Timing Belts are engineered to deliver accurate, slip-free movement and dependable synchronisation across a wide range of industrial applications. Constructed from high-quality thermoplastic polyurethane (PU) with a Shore hardness of 90±2 A, and reinforced with steel or Kevlar tensile cords, these belts provide high tensile strength, excellent wear resistance, and chemical stability, ensuring consistent performance even under demanding loads and high operating speeds.

Whether your system requires precise positioning in pick-and-place systems, synchronised conveying in packaging and automation, or reliable motion control in machinery and processing lines, our Timing Belts are designed to keep your operations running smoothly with low maintenance and long service life. Their quiet, low-vibration operation and resistance to oils, dust, moisture, and chemicals ensure system reliability, while their flexibility and ability to be welded on-site allow for quick installation and reduced downtime.

Precision & Slip-Free Motion

Ensures exact positioning and synchronisation, making it ideal for conveying and motion control systems that demand consistent speed without slip.

High Strength & Long Flex Life

Reinforced with steel or Kevlar cords for superior tensile strength and durability, maintaining stable performance even under continuous, high-speed operation.

Chemical & Temperature Resistant

Offers excellent resistance to oils, grease, moisture, dust, and many chemicals, with reliable operation in temperatures from -20°C up to +80°C for a wide range of industrial environments.

PU Timing Belts

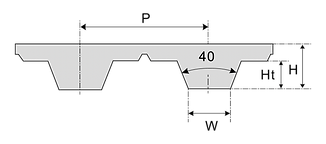

Type | P (mm) | W (mm) | Ht (mm) | H (mm) |

|---|---|---|---|---|

TT5 | 5 | 1.8 | 1.2 | 2.9 |

T5 | 5 | 1.8 | 1.2 | 2.2 |

T10 | 10 | 3.5 | 2.5 | 4.5 |

T20 | 20 | 6.5 | 4.5 | 8 |

Type | P (mm) | W (mm) | Ht (mm) | H (mm) |

|---|---|---|---|---|

AT5 | 5 | 2.5 | 1.2 | 2.7 |

AT10 | 10 | 5 | 2.5 | 4.5 |

AT20 | 20 | 10 | 5 | 8 |

Type | P (mm) | W (mm) | Ht (mm) | H (mm) |

|---|---|---|---|---|

H | 12.7 | 4.4 | 2.3 | 4.4 |

XH | 22.3 | 8 | 6.4 | 11.2 |

L | 9.5 | 3.2 | 1.9 | 3.6 |

XL | 5.1 | 1.4 | 1.3 | 2.3 |

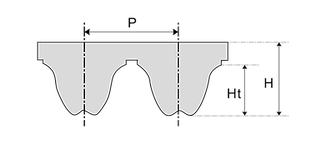

Type | P (mm) | Ht (mm) | H (mm) |

|---|---|---|---|

H3M | 3 | 2.2 | 2.4 |

H5M | 5 | 3.2 | 3.7 |

H8M | 8 | 5.6 | 5.6 |

H14M | 14 | 10 | 10 |

Type | P (mm) | Ht (mm) | H (mm) |

|---|---|---|---|

R3M | 3 | 1.2 | 2.1 |

R5M | 5 | 2 | 3.7 |

R8M | 8 | 3.4 | 5.6 |

R14M | 14 | 6.4 | 10 |

Customisation Options

-

Standard Open Length: 100 m (specific sizes available on request)

-

Coatings: Custom surface coatings for specific conveying or drive requirements available on request

-

Dimensions, tensile members, and colours: Fully customisable to meet your project needs

-

Tensile members: Available in Steel Cord and Aramid Fibre constructions

-

Colour Options: White, Black, Red, Blue, Yellow, and Grey

Available Profiles and Options